Metal Powder bakeng sa Filtration ea Polymer

Nalane ea Nts'etsopele ea Metal Powder Bakeng sa Polymer Filtration Media

PET PA PP e entsoeng ka polymer e phahameng e hloka ho hloekisoa pele fiber ea lik'hemik'hale e bilika ho tlosa litšila le likaroloana tsa gel tse kentsoeng ka har'a ho qhibiliha ho thibela ho phunyeha ha lesoba la spinneret, ho ntlafatsa boleng ba PET PA filament fiber, joalo ka likhoele tsa POY FDY. ;ha polymer e qhibilihisitsoeng e phalla ka har'a sekhahla sa skrine sa spin pack, khanyetso e hlahisoa, e le hore khohlano ea ho qhibiliha e hlahise mocheso, mocheso oa phahama, le thepa ea rheological ea ho qhibiliha e ntlafatsoe.Ka nako e ts'oanang, ho qhibiliha ho kopantsoe ka ho feletseng ho thibela phapang ea viscosity pakeng tsa ho qhibiliha;ho qhibiliha ho ajoa ka ho lekana ho lesoba le leng le le leng le lenyenyane la spinneret;ka keketseho ea nako ea ts'ebeliso ea filthara ea spin pack, litšila tse kahara mesh pack filter li tla eketseha, 'me khatello ea kopano e tla eketseha butle-butle.Khatello e eketsa lebelo ka potlako, 'me bophelo ba tšebeletso ea kopano bo khutšoanyane.Ha kopano e nyolohela khatellong e itseng, ho hlokahala hore ho nkeloe sebaka sa kopano ka nako, ho seng joalo, pompo ea metering e sithabetse, kapa spinneret e holofetse, kapa ho tsoa ho tsoa.

Khetho ea likarolo tse loketseng tsa filthara e bohlokoa haholo bakeng sa ho bilika ha fiber ea maiketsetso, 'me mecha ea litaba e nepahetseng ea sefa e bohlokoa haholo.Ts'ebetsong ea nts'etsopele ea ho ohla, hape ke mokhoa oa ho fumana mokhoa o nepahetseng oa ho kuta.Lisebelisoa tse ngata tse tsebahalang tsa filthara li kenyelletsa lehlabathe la leoatle, litšepe tse entsoeng ka tšepe, lifaha tsa khalase, lipoleiti tsa tšepe tse sirelelitsoeng, le likaroloana tsa tšepe tse sa bopehileng hantle.

Ntle le ho ba theko e tlase, mokhoa o loketseng oa ho sefa o tlameha ho ba le ho boloka porosity e phahameng likhatellong tse kopaneng nakong ea filthara ea polymer.E le ho boloka porosity e phahameng, bethe ea likaroloana tsa li-polymers tse chesang ka ho fetisisa ke tšekamelo ea ho etsa gel e bokellanang le ho fokotsa katleho ea ho hloekisa mecha ea litaba.Ka hona, lisebelisoa tse sefang tsa tšepe ha lia lokela ho kenya letsoho kapa ho kenya letsoho ho thehoeng ha li-gel.

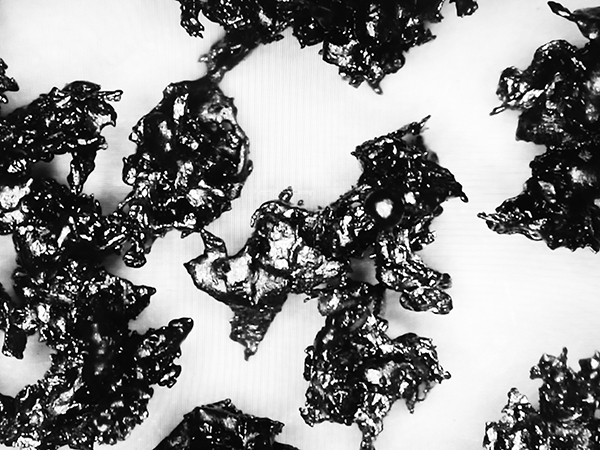

E fumaneha haholoanyane ho fumana lehlabathe la leoatle, empa e brittle haholo ka lebaka la hore nts'etsopele ea likaroloana tse ntle e atisa ho thibela li-capillaries ho li-spinnerets.Ho feta moo, sebaka se ikhethileng sa lehlabathe la leoatle se batla se le tlase haholo 'me se fokotsehile ka liperesente tsa porosity bakeng sa bophahamo bo bong le bo bong ba sefahla sa pakete, ka hona khatello ea pakete e tla eketseha haholo.Phofo ea tšepe e sa hloekang e lokiselitsoeng tlas'a maemo a itseng e bonts'a bokaholimo bo sa tsitsang haholo boo ka lebaka la boits'oaro bo tlase bo bonahalang, bo atisang ho ntlafatsa ts'ebetso ea eona ea ho sefa;tlas'a likhatello tsa ts'ebetso, e bonts'a boima bo bonahalang le ho matlafatsa ho hanyetsa ho hatelloa bakeng sa ts'ebetso e nepahetseng ea ho hloekisa ka mokhoa o fokolang kapa o se nang letho le ho putlama.

FUTAI Stainless Metal Powder Selection

FUTAI e sisinya lehlabathe la tšepe le sa hloekang la F-01 bakeng sa polyester POY FDY filament spinning e le mecha ea phatlalatso ea moruo;E le ho ntlafatsa boleng ba khoele, FUTAI e khothalletsa S-03, matla a phahameng a mochine le phofo e fokolang ea tšepe e nang le oxidization;Bakeng sa ts'ebeliso ea khatello e phahameng ea pele, S-04 ke khetho e lakatsehang bakeng sa khanyetso ea eona e matlafalitsoeng ea ho hatelloa, e kenellang haholo ho melts ea polymer, haholo bakeng sa ts'ebeliso ea PA filament spinning.

Mofuta oa Powder ea tšepe e se nang tšepe

| Mofuta | Fe(%) | N(%) | Kr(%) | Mn(%) | Si(%) | Mo(%) | C(%) | Lisebelisoa |

| F-01 | Bal. | Boholo.0.6 | 16-18 | Boholo.1.0 | 1.0-4.0 | - | Max.0.12 | Phofo ea tšepe ea moruo |

| S-03 | Bal. | 6-12 | 16-22 | Boholo.1.0 | 0.6-3.5 | Max.3.0 | Max.0.12 | Mecha ea litaba e tloaelehileng |

| S-04 | Bal. | Max.0.6 | 33-37 | Boholo.1.0 | 2-4 | - | Max.0.12 | Mecha ea litaba ea boemo bo holimo |

Melemo

1. Matla a phahameng a mochine.

2. Khanyetso e phahameng ea compaction.

3. Ho se tloaelehe ho phahameng.

4. Porosity e phahameng.

5. Haholo inert ho polymer qhibiliha.

6. Nako e telele ea bophelo ba spin pack.

7. Betere khoele boleng.

Mesh e fumanehang ka boholo le thepa ea eona ea 'mele

Ha o ntse o sebetsana le khoele ea filament, joalo ka khoele ea POY le FDY, ntho ea bohlokoa ka ho fetisisa ke ho kopanya mefuta e mengata e fapaneng ea phofo ho fumana phello e nepahetseng ea ho hloekisa.FUTAI e ka fa bareki bohle khetho e ntle ka ho fetisisa ea boholo ba marang-rang ho latela tsebo ea rona ea phofo ea tšepe e sa hloekang le liphihlelo tse ruileng mabapi le tlhahiso ea li-synthetic fiber spinning, e le hore bareki ba ka sebelisa melemo ea lehlabathe la tšepe ka botlalo. bophelo bohle ba spin pack le ho fihlela boleng bo botle ba likhoele tsa filament.

Mona ke lenane la boholo bo fumanehang ho latela ISO 4497 INTERNATION STANDARD FOR Metallic powders.Mefuta efe kapa efe e meng e ka hlahisoa ka kopo.

| Boholomicron | Bohololetlooeng | Boima bo bonahalangg/cm3 | Tlanya densityg/cm3 | Porosity % |

| 850/2000 | 10/20 | 1.45 | 1.95 | 75 |

| 500/850 | 20/30 | 1.55 | 2.10 | 73 |

| 350/500 | 30/40 | 1.60 | 2.10 | 71 |

| 250/350 | 40/60 | 1.65 | 2.60 | 67 |

| 180/250 | 60/80 | 1.80 | 2.70 | 65 |

| 150/180 | 80/100 | 2.00 | 2.90 | 62 |

| 125/150 | 100/120 | 2.22 | 3.10 | 58 |

| 90/125 | 120/170 | 2.50 | 3.20 | 56 |