Sistimi ea ho sefa bakeng sa ho sefa ha Melt Polymer

Sistimi ea ho sefa ea polymer ea Melt

Sistimi e qhibilihang ea polymer e bohlokoa lits'ebetsong tse ngata moo li-polymer li sebetsoang kapa li sebelisoang, joalo ka tlhahiso ea indasteri ea polymer ea PET/PA/PP, pre-polymerizaton, polymerization ea ho qetela, khoele ea likhoele, polyester staple fiber spinning, lifilimi tsa BOPET/BOPP. , kapa lera.Tsamaiso ena e thusa ho tlosa litšila, litšila, le likaroloana tse amang viscosity ho tloha polymer e entsoeng ka ho qhibilihisoa, ho netefatsa boleng le ho tsitsa ha sehlahisoa sa ho qetela.

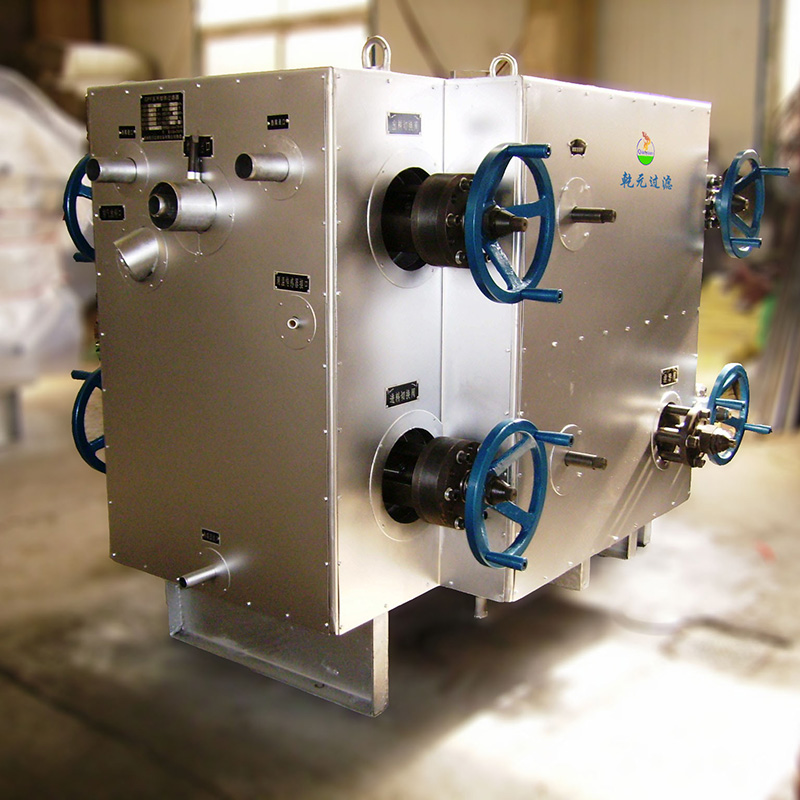

E le ho ntlafatsa boleng ba polymer e qhibilihisitsoeng le ho lelefatsa bophelo ba ts'ebeletso ea likarolo tsa pakete ea spin, filthara e tsoelang pele ea ho qhibiliha (CPF) e kenngoa phala e kholo ea ho qhibiliha.E ka tlosa likaroloana tsa litšila tsa mochini tse nang le bophara bo boholo ho feta 20-15μm ho qhibiliha, hape e na le mosebetsi oa homogenizing ho qhibiliha.Ka kakaretso tsamaiso ea ho hloekisa e na le likamore tse peli tsa sefe, 'me li-valve tsa litsela tse tharo li hokahane le phaephe e qhibilihang.Li-valve tsa litsela tse tharo li ka fetoloa nako le nako ho fetola tšebeliso ea liphaposi tsa ho hloekisa ho netefatsa hore ho na le ho hloekisa ho tsoelang pele.Ntlo ea kamore ea filthara e lahleloa ka karolo e le 'ngoe ka tšepe e sa hloekang.Filter ea sebaka se seholo e entsoe ka likarolo tse ngata tse nang le pleated candle filter.Karolo ea sefahla sa likerese e tšehetsoa ke silinda ea mantlha e nang le masoba, 'me lesela le ka ntle le na le mesh ea tšepe e le' ngoe kapa e mengata e mengata kapa sintered metal powder disc kapa multi-layers metal mesh & sintered fiber kapa sintered metal mesh, jj. ka sekhahla se fapaneng sa tlhoekiso se ipapisitseng le litlhoko tsa lihlahisoa tsa ho qetela.

Ka kakaretso ho na le mefuta e sa tšoaneng ea tsamaiso ea filtration, e kang Horizontal continuous filtration system, vertical continuous filtration system.Mohlala, nakong ea ts'ebetso ea ho bilika lichifi tsa PET, hangata ho khothaletsoa mofuta oa filthara ea mofuta oa kerese, o nang le sebaka sa ho sefa sa 0.5㎡ ka konokono ea kerese.Ho na le litlhophiso tse sebelisoang hangata tsa 2, 3, kapa 4 candle cores, tse tsamaellanang le libaka tsa filtration tsa 1, 1.5, kapa 2㎡, le matla a ts'oanang a ho qhibiliha a 150, 225, 300 kg/h.Sistimi ea filthara e otlolohileng e na le boholo bo boholo le ts'ebetso e rarahaneng, empa e na le melemo e mengata ho latela pono ea ts'ebetso: (1) E na le matla a maholo a mocheso, phapang e nyane ea mocheso oa ho qhibiliha, 'me ha ho na libaka tse shoeleng ha thepa e phalla.(2) Sebopeho sa baki ea ho itšireletsa sea utloahala, 'me mocheso o tšoana.(3) Ho bonolo ho phahamisa mokokotlo oa filthara ha u chencha filthara.

Phapang ea khatello pele le ka mor'a sefe e sa tsoa sebelisoa e tlase.Ha nako ea ts'ebeliso e ntse e eketseha, masoba a mahareng a sefa butle-butle aa thibeloa.Ha phapang ea khatello e fihla ho boleng ba ho beha, mohlala, joalo ka bakeng sa PET chips spinning, hangata palo e ka ba 5-7MPa, kamore ea sefate e tlameha ho fetoloa.Ha phapang e lumelletsoeng ea khatello e fetisitsoe, letlooeng la filthara le ka 'na la sotheha, boholo ba marang-rang bo eketseha,' me ho nepahala ha filtration ho fokotseha ho fihlela sefahla se phunyeha.Mokotla o fetotsoeng oa sefe o tlameha ho hloekisoa pele o sebelisoa hape.Ho hlaka ha phello ho khethoa ka ho fetisisa ke teko ea "bubble test", empa e ka boela ea ahloloa ho latela phapang ea khatello pele le ka mor'a sefe se sa tsoa fetoloa.Ka kakaretso, ha filthara ea likerese e phatlohile kapa e hloekisitsoe ka makhetlo a 10-20, ha e sa lokela ho sebelisoa.

Mohlala, bakeng sa li-filters tsa letoto la Barmag NSF, li futhumatsoa ke mouoane oa Biphenyl ka baki, empa mocheso oa mokelikeli o fetisang mocheso ha oa lokela ho feta 319 ℃, mme khatello e phahameng ea Biphenyl ke 0.25MPa.Khatello e phahameng ea moralo oa kamore ea filthara ke 25MPa.Phapang e phahameng e lumelletsoeng ea khatello pele le ka morao ho sefe ke 10MPa.

Tekheniki Parameters

| Mohlala | L | B | H | H1 | H2 | LOKISA(H3) | Inlet&Outlet DN(Φ/) | Sebaka sa Sefe(m2) | Screw Bar e sebetsang(Φ/) | Sekhahla se Hlatsoeng sa Phallo(kg/h) | Sefe Bolulo | Sefa Element | Kakaretso ea Boima(kg) |

| PF2T-0.5B | 900 | 1050 | 1350 | Joalo ka Sebaka sa bareki | 2200 | 22 | 2x0.5 | 65 | 40-80 | Φ158x565 | Φ35x425x4 | 660 | |

| PF2T-1.05B | 900 | 1050 | 1350 | 2200 | 30 | 2x1.05 | 90 | 100-180 | Φ172x600 | Φ35x425x7 | 690 | ||

| PF2T-1.26B | 900 | 1050 | 1390 | 2240 | 30 | 2x1.26 | 105 | 150-220 | Φ178x640 | Φ35x485x7 | 770 | ||

| PF2T-1.8B | 950 | 1140 | 1390 | 2240 | 40 | 2x1.8 | 120 | 220-320 | Φ235x620 | Φ35x425x12 | 980 | ||

| PF2T-1.95B | 950 | 1140 | 1390 | 2240 | 40 | 2x1.95 | 130 | 250-350 | Φ235x620 | Φ35x425x13 | 990 | ||

| PF2T-2.34B | 1030 | 1200 | 1430 | 2330 | 40 | 2x2.34 | 135 | 330-420 | Φ235x690 | Φ35x485x13 | 1290 | ||

| PF2T-2.7B | 1150 | 1200 | 1440 | 2350 | 50 | 2x2.7 | 150 | 400-500 | Φ260x690 | Φ35x485x15 | 1320 | ||

| PF2T-3.5B | 1150 | 1250 | 1440 | 2350 | 50 | 2x3.5 | 160 | 500-650 | Φ285x695 | Φ35x485x19 | 1450 | ||

| PF2T-4.0B | 1150 | 1250 | 1500 | 2400 | 50 | 2x4.0 | 170 | 600-750 | Φ285x735 | Φ35x525x19 | 1500 | ||

| PF2T-4.5B | 1150 | 1250 | 1550 | 2400 | 50 | 2x4.5 | 180 | 650-900 | Φ285x785 | Φ35x575x19 | 1550 | ||

| PF2T-5.5B | 1200 | 1300 | 1500 | 2350 | 50 | 2x5.5 | 190 | 800-1000 | Φ350x755 | Φ50x500x15 | 1650 | ||