Ho hloekisa lehlabathe hangata ho sebelisoa indastering ea peterole le indastering ea ho hloekisa metsi.Molao-motheo oa ho sefa lehlabathe le lehlohlojane haholo-holo ke ho sebelisa lihloela kapa lisebelisoa tsa ho sefa ho arola lehlabathe le lehlohlojane ho oli kapa metsi.Hare-hare ho filthara hangata e entsoe ka filthara mecha ea litaba, tse kang Johnson letlooeng, activated carbon, ceramics, filthara skrine, filthara element, joalo-joalo tsena filthara mecha ea litaba na le boholo bo fapaneng pore le liforomo tsa meralo, 'me e ka khethoa ho ea ka litlhoko tse fapaneng.Ha oli kapa metsi a feta sefeng, litšila tse kang lehlabathe le lejoe li qabeletsoe ka har'a sefe, ha oli e hloekileng kapa metsi a phalla ho tsoa ka ntle ho sefe.

Ho hloekisa lehlabathe hangata ho sebelisoa indastering ea peterole le indastering ea ho hloekisa metsi.Molao-motheo oa ho sefa lehlabathe le lehlohlojane haholo-holo ke ho sebelisa lihloela kapa lisebelisoa tsa ho sefa ho arola lehlabathe le lehlohlojane ho oli kapa metsi.Hare-hare ho filthara hangata e entsoe ka filthara mecha ea litaba, tse kang Johnson letlooeng, activated carbon, ceramics, filthara skrine, filthara element, joalo-joalo tsena filthara mecha ea litaba na le boholo bo fapaneng pore le liforomo tsa meralo, 'me e ka khethoa ho ea ka litlhoko tse fapaneng.Ha oli kapa metsi a feta sefeng, litšila tse kang lehlabathe le lejoe li qabeletsoe ka har'a sefe, ha oli e hloekileng kapa metsi a phalla ho tsoa ka ntle ho sefe.

Petroleum ke o mong oa mehloli ea bohlokoa ea matla indastering ea sejoale-joale.Leha ho le joalo, petroleum e atisa ho ba le mashala a sa tšoaneng, a tloaelehileng haholo a lehlabathe le likaroloana tsa lehlohlojane.Likaroloana tsena tsa lehlabathe li ka ama ts'ebetso ea oli, ts'ebetso le lipalangoang hampe, kahoo lehlabathe le sefang ke sehokelo sa bohlokoa indastering ea oli.

Bakeng sa ho sefa lehlabathe le lehlohlojane ka nepo, indasteri ea peterole e amohetse mekhoa le lisebelisoa tse fapaneng.Lintlha tse latelang li tla hlahisa mahlale a 'maloa a tloaelehileng le lisebelisoa tsa ho sefa lehlabathe le lehlohlojane:

Searohanyi: Se arola ke sesebelisoa se atisang ho sebelisoa ho sefa lehlabathe le lehlohlojane.E amohela molao-motheo oa karohano ea 'mele,' me e arola likaroloana tsa lehlabathe le lehlohlojane ho tloha ho oli ka matla a khoheli, matla a rotational centrifugal kapa matla a ho potoloha.Molao-motheo oa ho sebetsa oa karohano ke ho fetisa likaroloana tsa oli le lehlabathe ka sesebelisoa sa ho arohana ka har'a thepa, e le hore oli e ka feta hantle, ha likaroloana tsa lehlabathe li arohane.

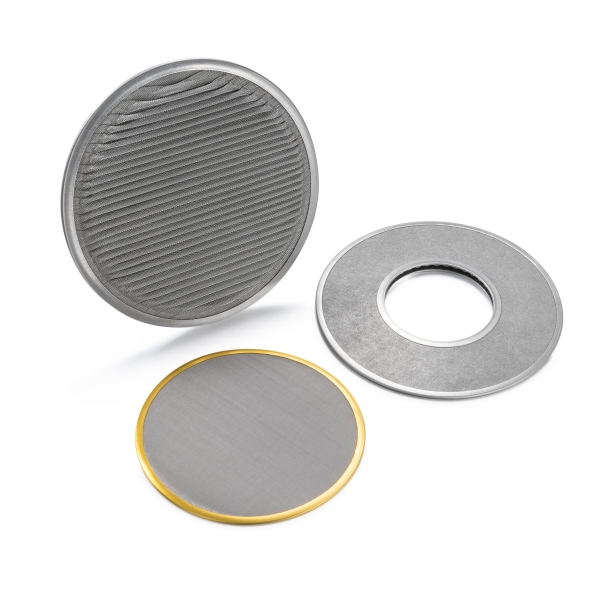

Li-sieves: Li-sieves ke mokhoa o mong o tloaelehileng oa ho sefa lehlabathe le lehlohlojane.E beha skrine ea sefe ka har'a phaephe ea oli ho thibela likaroloana tsa lehlabathe, ho lumella oli feela ho phalla.Sesefa skrine ka khetha fapaneng filthara fineness le filthara lintho tse bonahalang ho ea ka litlhoko.Nakong ea ts'ebeliso, filthara butle-butle e bokella sediment, ka hona, sefahla se hloka ho hloekisoa kapa ho nkeloa sebaka khafetsa.

Catcher: Catcher hape ke e 'ngoe ea lisebelisoa tse sebelisoang hangata ho sefa lehlabathe le lehlohlojane.E tšoara le ho bokella likaroloana tsa lehlabathe ka har'a oli ka ho beha lisebelisoa tsa ho tšoasa litlhapi.Hangata maraba a sebelisa libaskete kapa li-skrini ho tšoara likaroloana, tse tlosoa ka lisebelisoa tsa ho hloekisa.Khetho le moralo oa maraba li ela hloko boholo le boima ba likaroloana tsa lehlabathe, hammoho le litlhoko tsa phallo ea oli.

Sesefa sa Centrifugal: Sefefo sa Centrifugal ke sesebelisoa se sebetsang hantle sa ho sefa lehlabathe le lehlohlojane.E sebelisa matla a centrifugal ho arola likaroloana tsa lehlabathe ka har'a oli.Ka ho lokisa lebelo la ho potoloha la sefe ea centrifugal le ho rala matla a loketseng a centrifugal, ho hloekisa lehlabathe le lehlohlojane hantle ho ka finyelloa.Li-filters tsa Centrifugal hangata li khona ho sebetsana le oli e ngata 'me li khona ho arola likaroloana tsa lehlabathe kapele le ka mokhoa o nepahetseng.

Ha u khetha le ho sebelisa mekhoa le lisebelisoa tsa ho sefa lehlabathe le majoe, lintlha tse kang litšobotsi tsa oli, boholo le mahloriso a likaroloana tsa lehlabathe le majoe, le phallo ea oli li lokela ho nkoa.Ho phaella moo, tlhokomelo ea kamehla le ho hloekisa lisebelisoa tsa filthara le tsona ke tsa bohlokoa haholo ho netefatsa ts'ebetso ea eona e tloaelehileng le phello ea ho sefa.

Ho sefa lehlabathe ke sehokelo sa bohlokoa indastering ea peterole.Ka khetho e nepahetseng le tšebeliso e nepahetseng ea theknoloji le lisebelisoa tsa ho hloekisa, boleng ba oli bo ka ntlafatsoa, kotsi ea tšenyo ea lisebelisoa e ka fokotseha, 'me ts'ebetso e tsoelang pele le e sebetsang ea tlhahiso ea oli e ka tiisetsoa.Likhamphani tsa petroleum li lokela ho ela hloko mosebetsi oa ho sefa lehlabathe le lehlohlojane, 'me li lule li ela hloko mahlale a macha le lisebelisoa, e le ho tsoela pele ho ntlafatsa ts'ebetso le phello ea ho sefa.

Metsi ke o mong oa mehloli ea bohlokoahali bophelong ba rona.Leha ho le joalo, mehloli ea metsi e atisa ho ba le litšila tse sa tšoaneng, tse tloaelehileng le tse tloaelehileng tsa tsona ke lehlabathe le likaroloana tsa majoe.Likaroloana tsena tsa lehlabathe li ka baka mathata a mangata mehloling ea metsi, tse kang ho ama boleng ba metsi, ho koala lipeipi le lisebelisoa tse senyang.Ka hona, ho sefa lehlabathe le lehlohlojane ho fetohile mohato oa bohlokoa ho hloekiseng mehloli ea metsi.

Molao-motheo oa ho hloekisa lehlabathe le lejoe ka metsing o itšetlehile ka 'nete ea hore likaroloana tse nang le boholo bo boholo ba likaroloana li ke ke tsa feta ka har'a li-pores tsa sefa, kahoo li finyella ho arohana ha metsi le likaroloana.Bongata ba pore le sebopeho sa sefe li etsa qeto ea boholo le mofuta oa ntho e ka tlosoang.Lisebelisoa tse sebelisoang hangata li kenyelletsa lehlabathe la quartz, activated carbon, ceramics, joalo-joalo.

E le ho hloekisa lehlabathe le lehlohlojane ka katleho, re ka sebelisa mekhoa le lisebelisoa tse fapaneng.Lintlha tse latelang li tla hlahisa mahlale a 'maloa a tloaelehileng le lisebelisoa tsa ho sefa lehlabathe le lejoe ka metsing:

Ho kenella: Ho kenella ke mokhoa o bonolo le o sebetsang oa ho sefa.E sebelisa lisebelisoa tsa filthara tse ngata, joalo ka lehlabathe la quartz, k'habone e kentsoeng, joalo-joalo, ho sefa likaroloana tsa lehlabathe le lehlohlojane ka har'a adsorption ea intermolecular le tlhahlobo.Ka ts'ebetsong ea ho kenella, metsi a phunyeletsa ho tloha karolong e ka holimo 'me a hloekisoa ka lera ka lisebelisoa tsa filter ea fineness e fapaneng.Mokhoa ona o ka tlosa ka katleho likaroloana tsa lehlabathe ka metsing, hape o tlosa palo e itseng ea lintho tse phelang tse qhibilihisitsoeng le likokoana-hloko.

Sedimentation: Sedimentation ke mokhoa oa ho lokisa likaroloana tsa lehlabathe ka matla a khoheli.Re ka etsa sena ka litanka tsa sedimentation kapa bajaki.Nakong ea sedimentation, metsi a sebetsa ka ho fokotsa ho phalla, ho etsa hore likaroloana tsa lehlabathe li tebe ka lebaka la matla a khoheli.Likaroloana tse khōloanyane tsa lehlabathe li lula fatše kapele, ha likaroloana tse nyenyane li teba butle.Ka ho laola nako ea sedimentation le botebo ba tanka ea sedimentation, likaroloana tsa lehlabathe tsa boholo bo fapaneng li ka tlosoa.

Sieving: Sieving ke mokhoa oa ho sefa likaroloana tsa lehlabathe ka letlooeng la boholo ba pore.Re ka beha lisebelisoa tsa ho hlahloba tse kang li-skrini kapa li-filters mohloling oa metsi.Lisebelisoa tsena tsa ho hlahloba li na le li-pores tse boholo bo fapaneng ho khetha lehlabathe le likaroloana tsa lehlohlojane.Likaroloana tse kholo li tla sefa ebe metsi a hloekileng a tla feta.Mokhoa oa sieving o bonolo ebile o sebetsa hantle 'me hangata o sebelisetsoa ho hloekisa likaroloana tse kholoanyane.

Bohlokoa ba ho sefa lehlabathe le lehlohlojane bo ke ke ba hlokomolohuoa.Likaroloana tsa lehlabathe li ke ke tsa ama feela pepeneneng le tatso ea metsi, empa hape li tla ba le litlamorao tse mpe lits'ebetsong le lisebelisoa tsa mohloli oa metsi.Likaroloana tsa lehlabathe li ka koala liphaephe, ho phalla butle ha metsi, ho eketsa tšebeliso ea matla, le ho baka ho senyeha le ho senyeha ha thepa.Ho sefa kamehla ha lehlabathe le lehlohlojane ho ke ke ha netefatsa tšireletseho le likhoerekhoere tsa mehloli ea metsi feela, empa hape ho lelefatsa bophelo ba litšebeletso tsa lipeipi le lisebelisoa le ho fokotsa litšenyehelo tsa tlhokomelo.