Tlhahisong ea indasteri, oli ke ntho ea bohlokoahali ebile e bohlokoa.Tlhophiso ea oli e arotsoe ka mekhahlelo e 'meli:

Tlhahisong ea indasteri, oli ke ntho ea bohlokoahali ebile e bohlokoa.Tlhophiso ea oli e arotsoe ka mekhahlelo e 'meli:

1. Oli e tala

Oli e tala ke motsoako o rarahaneng o nang le li-hydrocarbon tse fapaneng, sulfide, metsoako ea naetrojene, joalo-joalo, e ka bakang tšenyo ea lisebelisoa le tikoloho.Ka hona, hoa hlokahala ho sefa oli e tala.

Sepheo sa ho sefa oli e tala ke ho tlosa litšila, ho ntlafatsa bohloeki ba oli e tala, le ho netefatsa ts'ebetso e tloaelehileng ea ts'ebetso e latelang.Ka nako e ts'oanang, oli e tala e tlhotliloeng e ka fokotsa ho bola le ho senyeha ha lisebelisoa le ho lelefatsa bophelo ba ts'ebeletso ea lisebelisoa.

2. Oli e hloekisitsoeng

Oli e hloekisitsoeng e hlahisoa le ho sebetsoa ka oli e sa hloekang, joalo ka oli e tlotsang, oli ea hydraulic, oli ea mafura, joalo-joalo Lioli tsena li ka silafala nakong ea ts'ebeliso, tsa baka ho senyeha ha lisebelisoa.

Lintho tse lokelang ho hloekisoa ka har'a oli haholo-holo li kenyelletsa lintho tse tiileng tse emisitsoeng, likaroloana, phofo ea tšepe, lik'hemik'hale tse kotsi, likokoana-hloko, joalo-joalo. Litšila tsena li tla ama phello ea lubrication ea thepa, ho potlakisa ho apara ha thepa, esita le ho baka ho hloleha hoa thepa.Ka hona, ho hloekisa oli ho fetohile mokhoa oa bohlokoa oa ho netefatsa ts'ebetso e tloaelehileng ea lisebelisoa

Molao-motheo oa tlhoekiso ea oli haholo-holo ke ho arola lintho tse emisitsoeng joalo ka litšila, lintho tse itseng le phofo ea tšepe ka har'a oli ka sesefo.Ts'ebetso ena e itšetlehile haholo ka khetho ea mecha ea litaba ea filthara le moralo oa filthara.Mecha ea litaba e sebelisoang ka tloaelo e kenyelletsa pampiri ea filthara, skrine ea filthara, k'hothone ea filthara, joalo-joalo, e nang le ho nepahala ho fapaneng le ho hanyetsa khatello.

Ho na le mefuta e mengata ea ho sefa oli, ho kenyelletsa le ho sefa ka mochini, ho sefa lik'hemik'hale le ho sefa ha baeloji.Mechanical filtration haholo-holo ke ho sefa likaroloana tse kholo, litšila le lintho tse ling tse fanyehiloeng ka har'a oli ka mecha ea litaba e kang sefahla kapa pampiri ea sefe.Ho hloekisa lik'hemik'hale ke ho sefa lik'hemik'hale tse kotsi ka har'a oli ka mekhoa ea lik'hemik'hale e kang adsorption, precipitation, le ion exchange.Bio-filtration ke ho sefa likokoana-hloko le menko ka har'a oli ka lintho tsa tlhaho tse kang li-enzyme tsa tlhaho kapa khabone e kentsoeng.

Lits'ebetsong tse sebetsang, tlhoekiso ea oli e hloka ho nahana ka maemo le litlhoko tse fapaneng tsa ts'ebetso.Ka mohlala, tlas'a boemo ba viscosity e phahameng le mojaro o phahameng, ho hlokahala hore u khethe thepa ea filthara e nang le matla a phahameng le ho hanyetsa mocheso o phahameng;athe bakeng sa boemo ba viscosity e tlaase le mojaro o tlaase, ho hlokahala hore u khethe lisebelisoa tsa filthara tse lebisang tlhokomelo e eketsehileng ho bohloeki.Ho phaella moo, bakeng sa mefuta e fapaneng ea lihlahisoa tsa oli, ho boetse hoa hlokahala ho khetha mekhoa le lihlahisoa tse loketseng tsa ho hloekisa.

Tlhophiso ea oli e hloka ho ela hloko lintlha tse latelang:

Filtration fineness:Ho khetha mokhoa o nepahetseng oa ho hloekisa ho ka tlosa litšila ka har'a oli ka katleho, 'me ka nako e ts'oanang, ho hloekisa ka mokhoa o feteletseng ho ke ke ha lebisa ho fokotseha ha boleng ba oli.

Khatello ea ho hanyetsa:lihlahisoa tsa ho hloekisa oli li hloka ho ba le khatello e lekaneng ea ho hanyetsa ho mamella ts'ebetso ea ho hloekisa tlas'a phapang e phahameng ea khatello.

Tšebelisano ea Lik'hemik'hale:Oli e na le mefuta e sa tšoaneng ea lik'hemik'hale, 'me lihlahisoa tsa ho hloekisa li lokela ho lumellana le lik'hemik'hale tsena ntle le lik'hemik'hale kapa ho bola.

Bokhoni ba ho thibela tšilafalo:Lihlahisoa tsa ho hloekisa li hloka ho ba le bokhoni bo botle ba ho thibela tšilafalo, bo ka khonang ho tlosa litšila ka katleho ka oli, 'me ka nako e ts'oanang, ha ho bonolo ho thijoa kapa ho silafatsoa.

Bonolo ba tlhokomelo:Bonolo ba tlhokomelo ea lihlahisoa tsa filtration le tsona ke ntlha e lokelang ho nahanoa, ho kenyeletsoa bothata le litšenyehelo tsa ho nkela likarolo tsa sefa sebaka le ho hloekisa maqephe a sefa.

Ka bokhutšoanyane, ho hloekisa oli ke sehokelo sa bohlokoa ho netefatsa tlhahiso ea indasteri.Ka ho khetha lihlahisoa tse loketseng tsa ho hloekisa oli, litšila tse ka har'a oli li ka tlosoa ka katleho, ho hloeka ha oli ho ka ntlafatsoa, 'me ts'ebetso e tloaelehileng ea ts'ebetso e latelang e ka tiisetsoa.Ka nako e ts'oanang, oli e hloekisitsoeng e ka boela ea fokotsa ho bola le ho senyeha ha lisebelisoa le ho lelefatsa bophelo ba tšebeletso ea lisebelisoa.

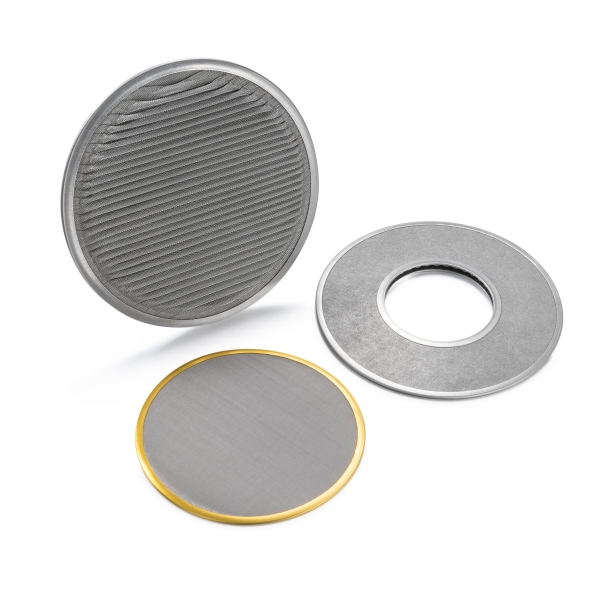

Khamphani ea rona e fana ka lihlahisoa tsa ho hloekisa oli tse kang li-filters, li-filters, li-spin pack filters, Pack screens, gaskets, wire mesh demisters, Wire Mesh Corrugated Packing, joalo-joalo. Lihlahisoa tsena li na le ho nepahala ho fapaneng ho hloekisa, ho hanyetsa khatello le bophelo ba tšebeletso, li hloka ho khethoa. ho ya ka maemo a fapaneng a tshebetso le ditlhoko.Re ka etsa lihlahisoa tsa litlhaloso tse fapaneng, boholo le ho nepahala ha filthara ho latela litlhoko tsa bareki.